- #MATRIX VINYL LATTICE PANELS HOW TO#

- #MATRIX VINYL LATTICE PANELS FULL#

- #MATRIX VINYL LATTICE PANELS PLUS#

#MATRIX VINYL LATTICE PANELS FULL#

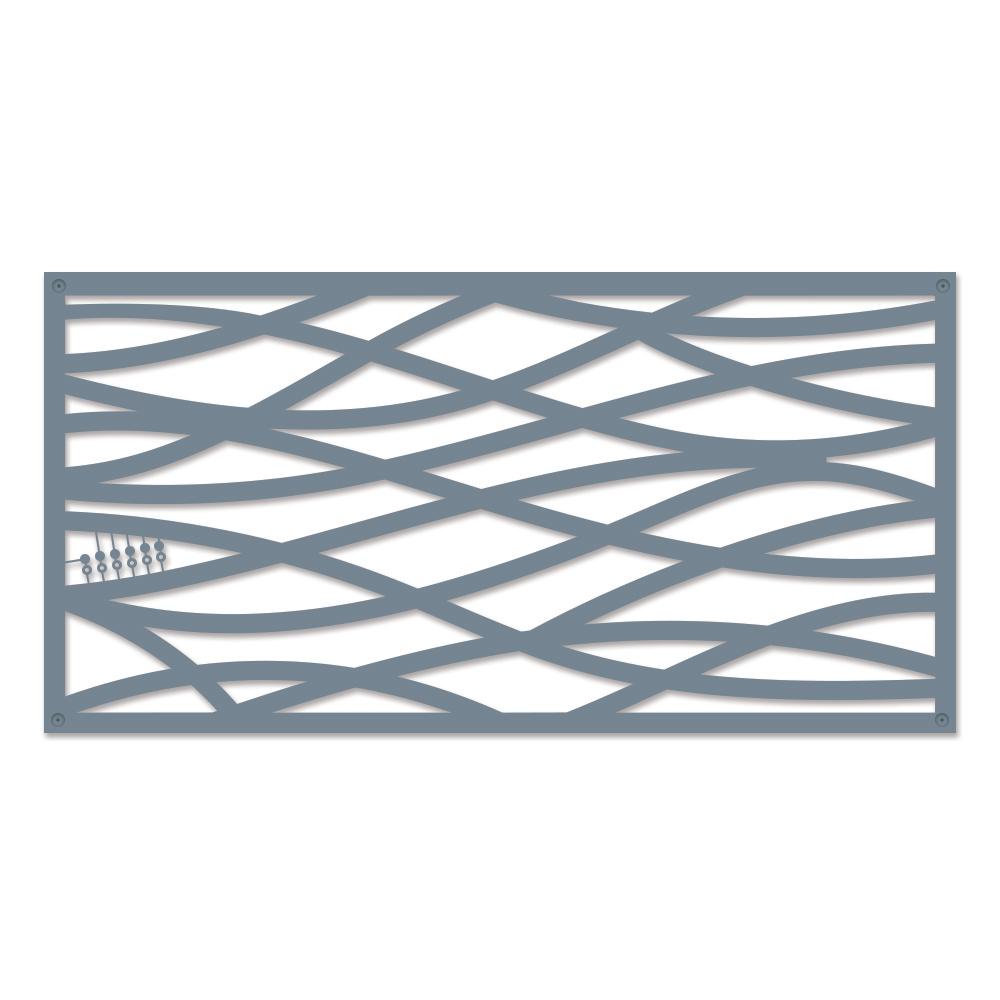

Finishing options include painting and, more recently, trimming and full assembly. Today, ÉireComposites manufactures parts for customers globally, and offers design, tooling manufacture and manufacturing processes such as resin transfer molding (RTM) and autoclave cure for prepreg parts. In 2008, ÉireComposites’ first aerospace parts flew on an IAE V2500 engine. From there, the company connected with and began making parts for Tier 1 aerospace supplier Bombardier (which became Spirit AeroSystems when acquired in 2020) in Belfast, Northern Ireland, U.K. Before moving into commercial aerospace parts, ÉireComposites started with R&D work for space, thanks to funding from the European Space Agency (ESA). McKeigue leads CW into an area of the floor where aerospace parts are manufactured and stored. The full 1.5-meter-diameter demonstrator was on display during the JEC World 2022 trade show in Paris, France, in May 2022. “You’ve got continuous fibers running in each angle and rib direction,” he notes. The tapes ultimately consolidate, via autoclave, to the same thickness throughout, even at the overlaps. These tapes are manually layered one by one in a specific order to make sure they overlap in the right places. McKeigue says the final structure weighs only 9.8 kilograms and was easily able to withstand the design compression load of 175 kilonewtons. The key to its manufacture, he explains during the tour, is intricate layup of the tapes, which comprise Toray Advanced Composites’ (Nijverdal, Netherlands) epoxy prepreg system RS36, with Toray M55J high-modulus fibers as a unidirectional (UD) reinforcement. The goal was to build an ultra-strong, lightweight cylinder that could be used as the central structure on a satellite, with the grid-stiffened lattice design replacing traditional sandwich construction. (Galway, Ireland), the Irish subsidiary of space and defense technology company ATG Europe (Noordwijk, Netherlands).

This is a demonstrator project with ATG Innovation Ltd. One is a small-scale version of a 1.5-meter-radius cylinder formed as a lattice of interwoven tapes.

#MATRIX VINYL LATTICE PANELS HOW TO#

“We’ve strengthened a lot in terms of how to run a business, and we’ve brought in some new people, and we’ve invested a bit more in factory technology and some of the software systems that run in the background,” he says.ĬW’s tour, led by McKeigue, begins with a number of samples from completed projects.

#MATRIX VINYL LATTICE PANELS PLUS#

This change, plus other staff changes such as the hiring of Mark McKeigue as chief commercial officer in 2020, enabled the company to focus not only on interesting projects, but on projects that have more strategic commercial value, Flanagan says. In 2018, management and investors shifted within ÉireComposites, resulting in the original co-founders and managers leaving the company and Flanagan becoming CEO.

He says the R&D focus tends to attract top engineering and manufacturing candidates - “because what we’re doing is interesting, and it’s novel, and I think that helps us to get really smart people.”įlanagan first came on board in 2014 as R&D director. “Because the company was a spinoff from the university, it’s always had a really strong research ethos,” Flanagan explains. Less than a year after CTL was founded, ÉireComposites was started as a separate branch of the company, focused on composite parts fabrication. Growing out of the University of Ireland, and building on Feerick’s background in plastics and Ó Brádaigh’s academic work in composites engineering, the company began first as a composite materials testing company called Composites Testing Laboratory (CTL), which remains a subsidiary of ÉireComposites today. The company that is now ÉireComposites was originally founded in 1998 by co-founders Conchúr Ó Brádaigh and P.J. “We’ve always had big interests in renewables and in aerospace,” Tomás Flanagan, CEO, explains. In the case of ÉireComposites (Galway, Ireland), the focus has always been on core materials and process capabilities that can be translated to a wide range of end markets. Many fabricators tend to focus on one specific end market area. Here, the company leverages its materials and process experience and R&D focus toward commercial projects ranging from civil aviation, to wind and tidal energy and specialty equine saddles.

“Irish” Composites. ÉireComposites - “Éire” meaning “Ireland” in the Irish Gaelic language - operates a 6,000-square-meter facility in Galway, Ireland.

0 kommentar(er)

0 kommentar(er)